Our black series pumps for fecal waters are known by their durability, reliable operation, long lifetime and robust constructions. The customers could deside for fittings which enables them to move the pump from shaft to shaft with ease.

The pumps for fecal waters from our black series are intented to use:

In pumping arrangement in household and industrial wastewater, which does not contain solid particles or sand. Wastewaters could include soft fibres.

In fecal water pumping arrangements (household, farms, industry).

In sewage treatment plants.

As pumping stations.

In construction industry (construction pits, flooded constructions or shafts).

Users can choose between 3 different capacity ranges and types:

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATERS

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER – VORTEX (passage 60mm)

MEDIUM CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER

LARGE CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER

Pumps from black series are characterized by the following features and are available in custom-made configuration:

Pumps are portable and made of impact-resistant and durable aluminium alloy.

Pumps equipped with motors for various voltage and frequence levels.

Pumps fitted with single-phase motors are equipped with terminal boxes housing start capacitors.

Pumps fitted with 3-phase motors are equipped with cables (8m or 10m).

Control panels tailored to customer specifications are available for all pumps.

Design could be also free flow, requested by the costumer.

The oil meets ecological requirements and is environmentally safe in case of accidental spillage.

Spare parts for all types of pumps are available.

All detailed descriptions and characteristics are available in catalogue which you can recive via E-mail. Write us on our E-mail info@s-ei.eu

Following your request via E-mail you will recive current price lists. We are available on: info@s-ei.eu

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATERS

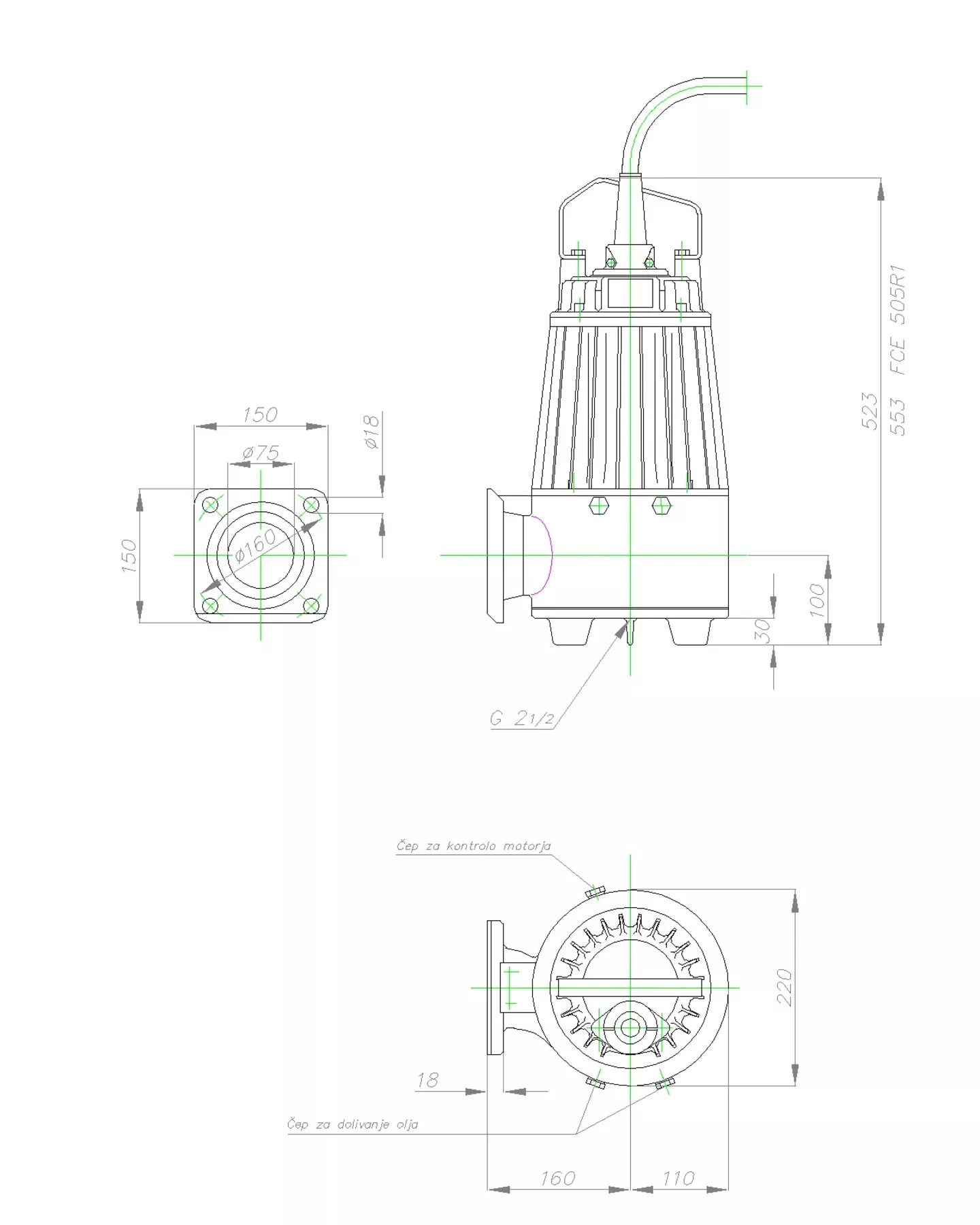

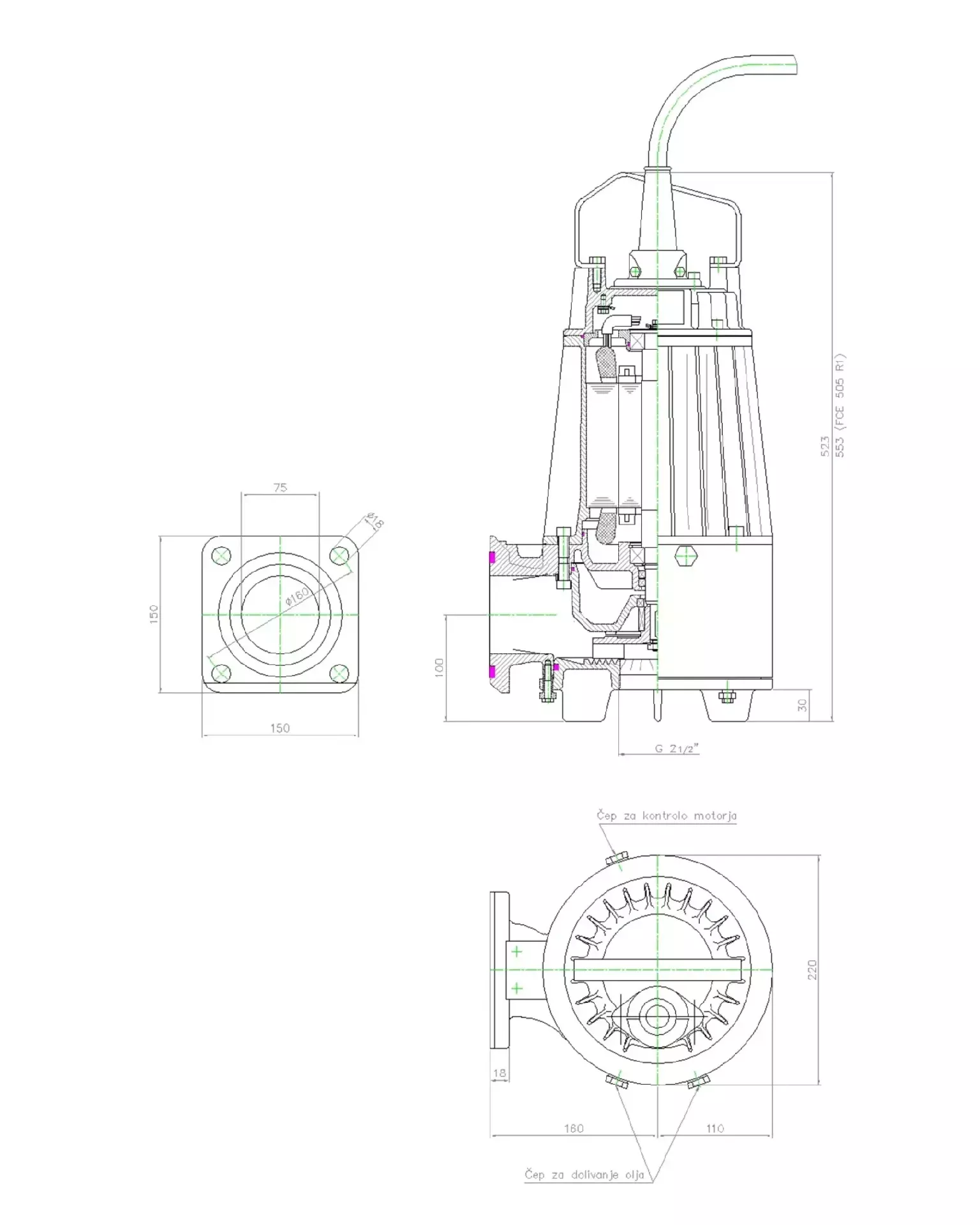

FC(E) 305-510 types

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

FC (E) 305-510 submersible pumps are used for pumping domestic and industrial effluents and all wastewater that does not contain solid particles and sand. Only soft fibrous particles may be present in the effluent. The temperature of the liquid and the surroundings must not exceed 40°C. Manufactured with single- or three-phase underwater electric motors in dry design, the pumps are robust, made with gray cast iron components.

Pumping part: The pumps are single stage, made in a monoblock version with a joint shaft of the pump and the electric motor. The space between the pump and the electric motor is partially filled with oil which allows dry running as the oil cools and lubricates the sliding seals. The properties of the oil meet ecological requirements and do not pose a danger to the environment in the event of a spill. The open impeller version allows the passage of lumpy fibrous particles with a diameter of 10 to 100 mm. When combined with a chopping board, the impeller cuts the fibrous impurities in the pumped liquid to prevent clogging of the pipeline. A free-flow pump is also possible. The housings are made of gray cast iron, while shafts and screws are made of stainless steel and are resistant to mild acids, sludge water and silicates.

Electric motor: Underwater single-phase or three-phase asynchronous motor cooled with ambient medium temperature up to 40°C with additional power for operation in unsinkable version. The winding is of class F (155°C) with IP68 degree of protection. Single-phase motors have a permanently connected electrical cabinet (with capacitors), while three-phase motors have only a cable with the lengths of 8 and 10 m. The electric motor is dimensioned in such a way that it also allows a dry installation of the pump next to the collector.

Pump installation: Wet installation (stable or portable) is common, as the pump is immersed in the liquid it is pumping. In doing so, the liquid cools the electric motor. With a stable installation in the shaft, an accessory with a lock is used, which enables quick installation of the pump and easy lifting of the pump without entering the shaft during maintenance work. With the accessories, two 2″ pipes are installed in the shaft which guide the pump when lowered into the shaft. Portable pumps, which are moved from shaft to shaft, are equipped with accessories that contain elbows for the connection of flexible pipes. The pumps are therefore equipped with a threaded or flanged suction connection, as shown in the sketches in the catalog. The fluid level in the manifold must always be above the pump pressure connection. This will prevent the formation of an air bag in the pump. Therefore, with FC(E) pumps, the corresponding accessories can also be used for mounting, as the P-FC-Z accessories can be used to quickly lower and automatically connect the pump in the shaft, and the P-FC-P accessories can be used to equip portable pumps.

FITTINGS:

Lock fitting P-FC-Z 80 for pumps with DN 80 connection

Fitting for portable version P-FC-P 80 for pumps with DN 80 connection

Main purposes of use:

for biological wastewater or feces pumping systems

fecal water pumping

industrial purposes

for treatment plants

for pumping stations

agriculture

home use

construction

construction grounds, flooded basements, shafts

Technical characteristics:

Flow: from 36 to 54m3/h

Lifting pumping height: up to 16m

Engine power: 0.85 ÷ 1.8kW

Power supply: 1-phase (230V), or 3-phase (400V),

Medium temperature: from 0°C to + 40°C

Installation depth: up to 10m in the medium

Weight: 30 – 35kg

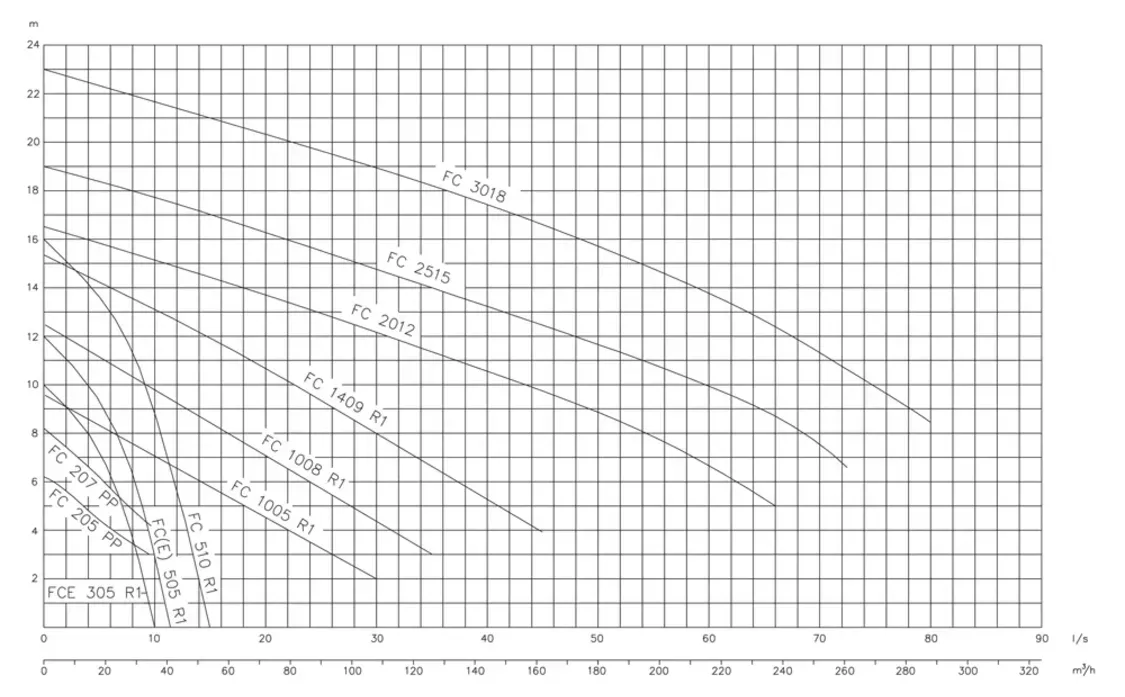

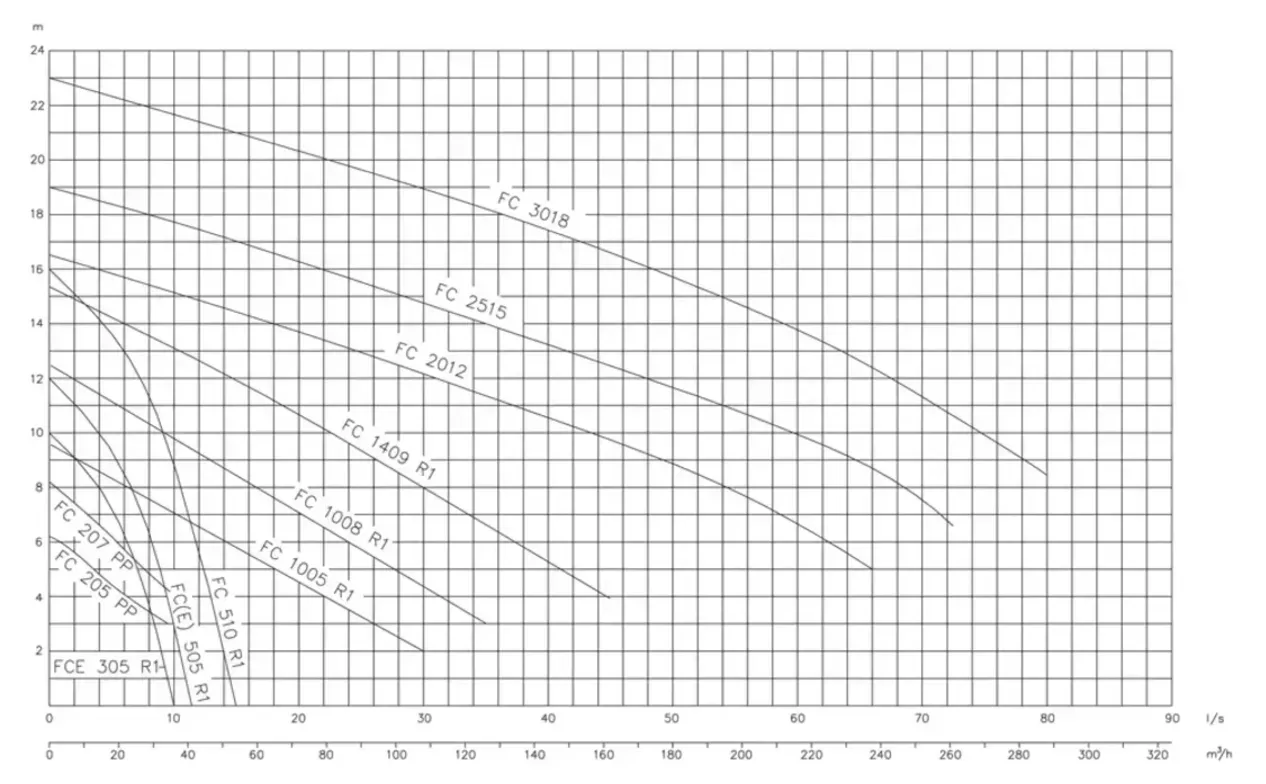

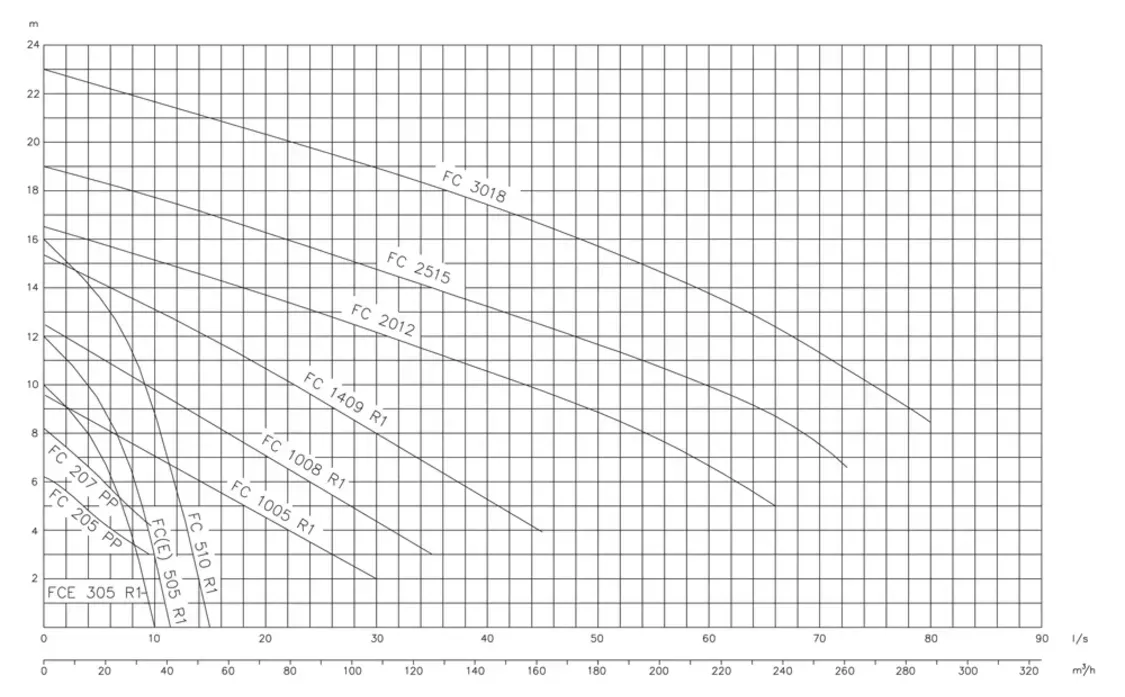

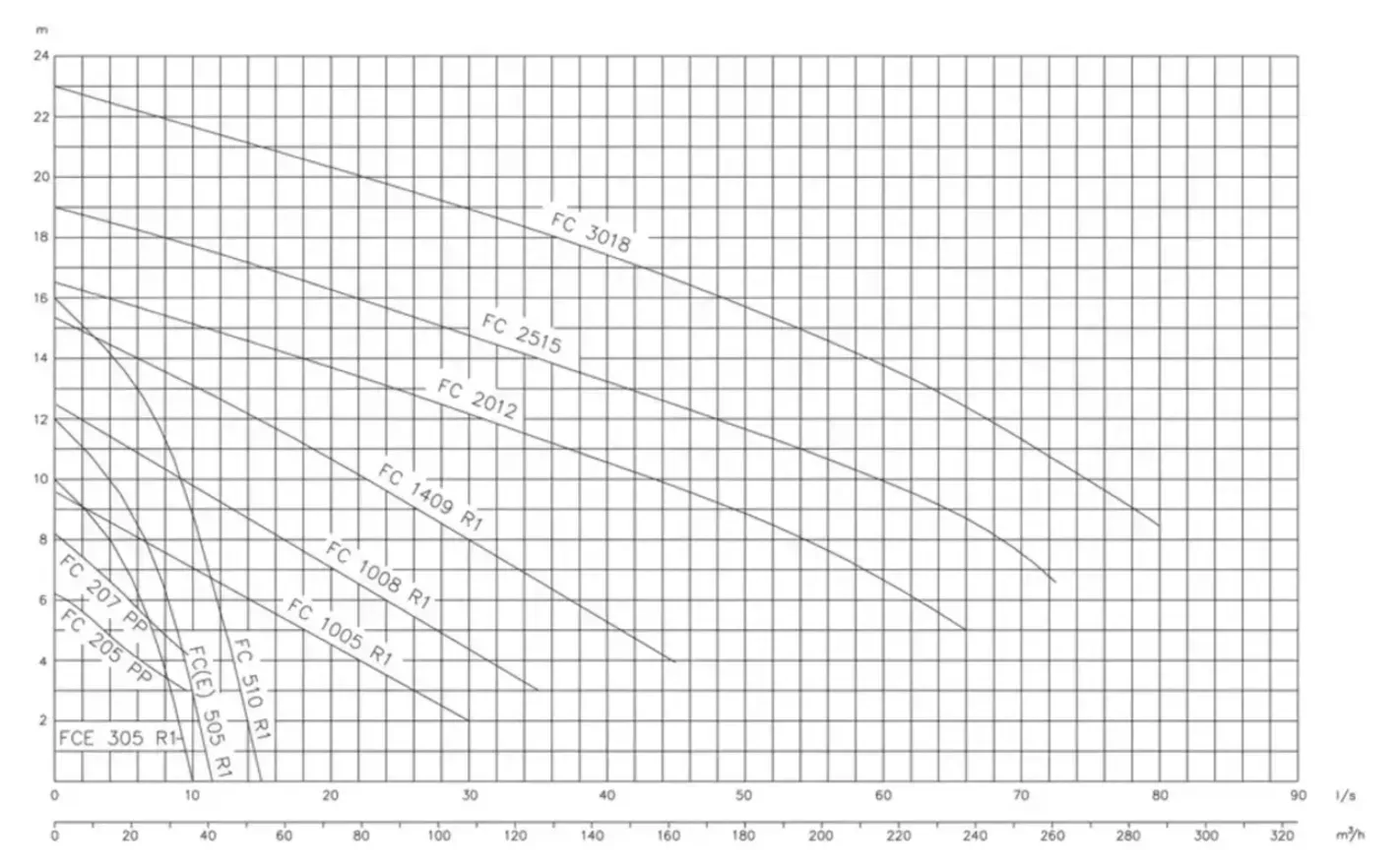

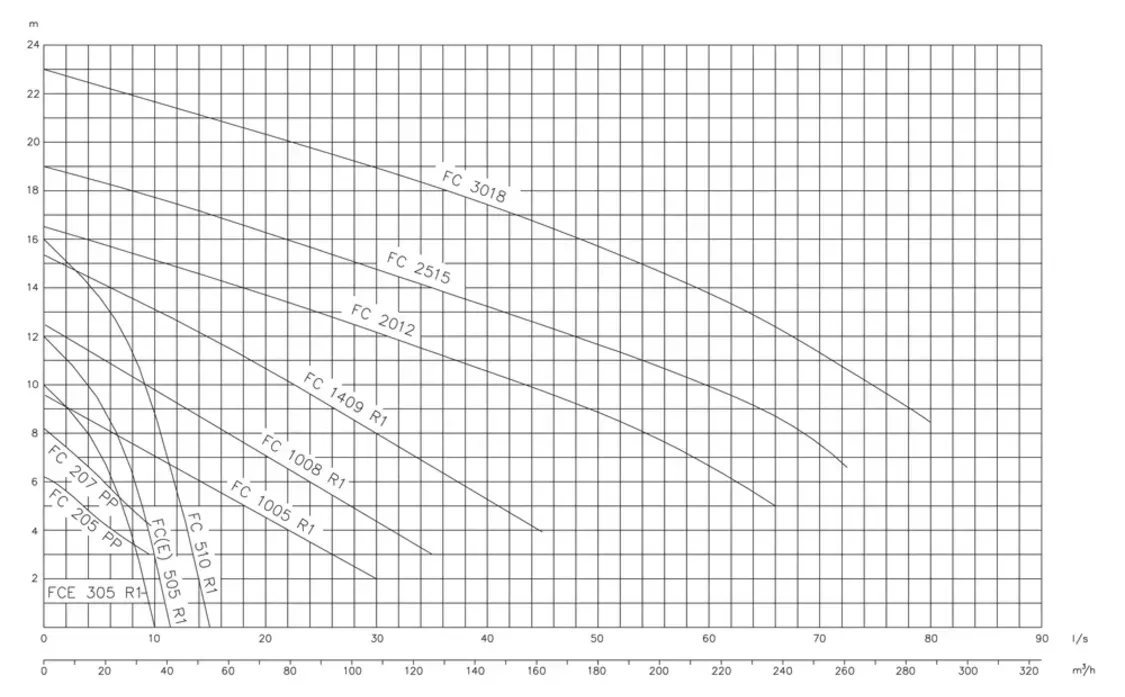

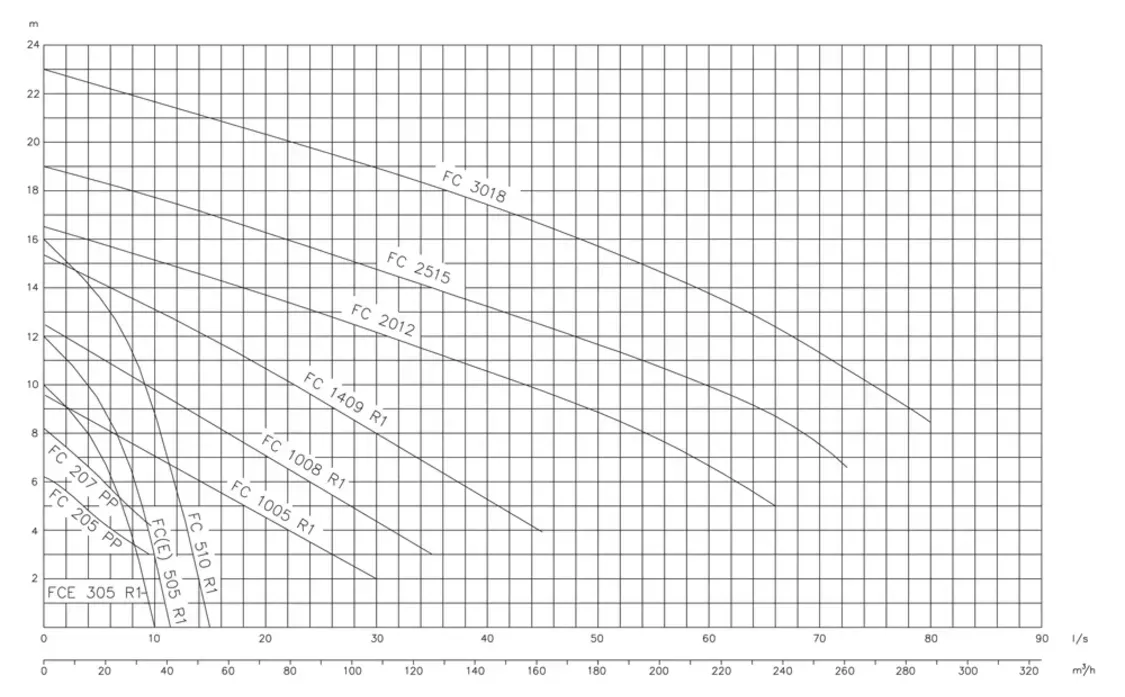

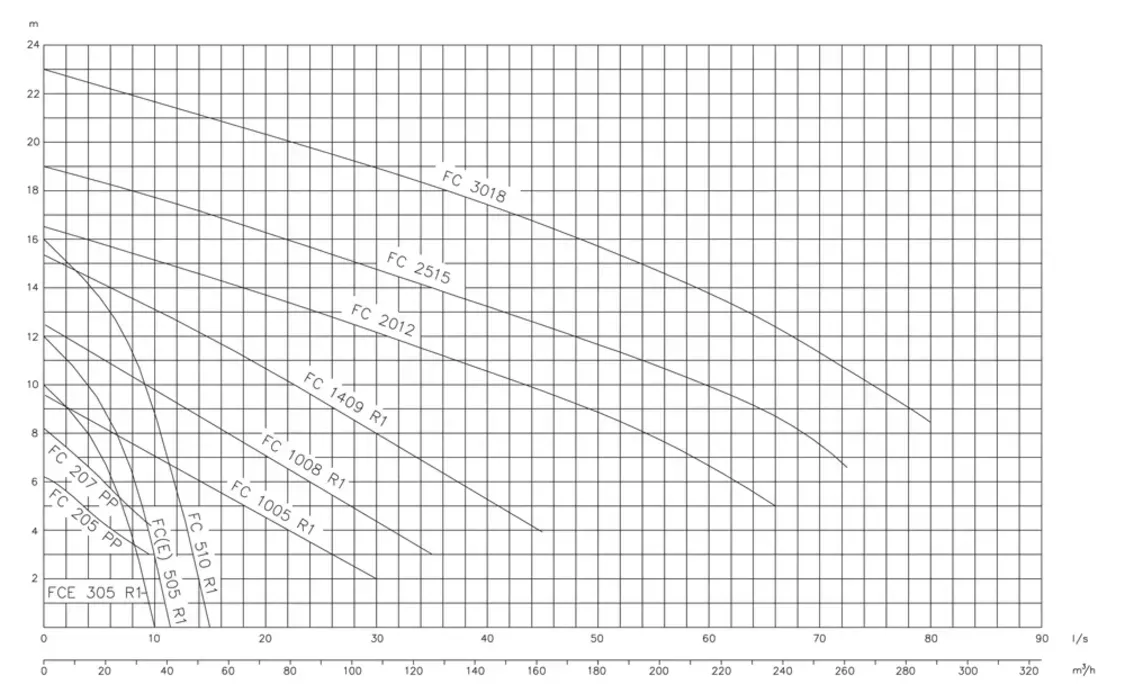

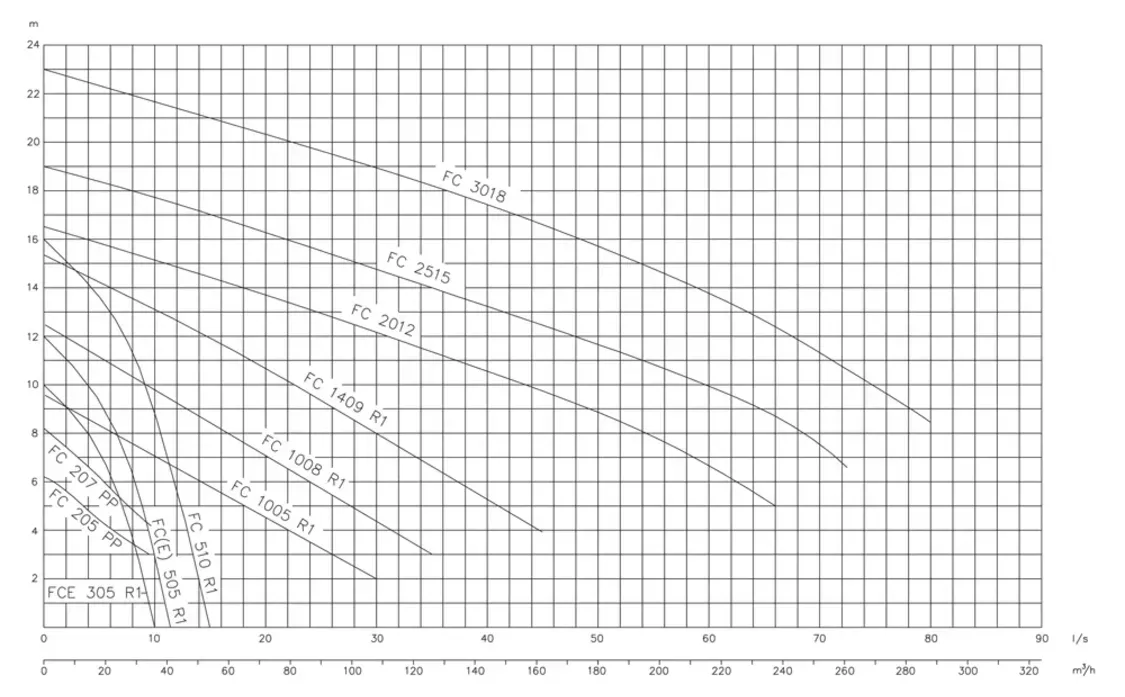

Small capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

Small capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

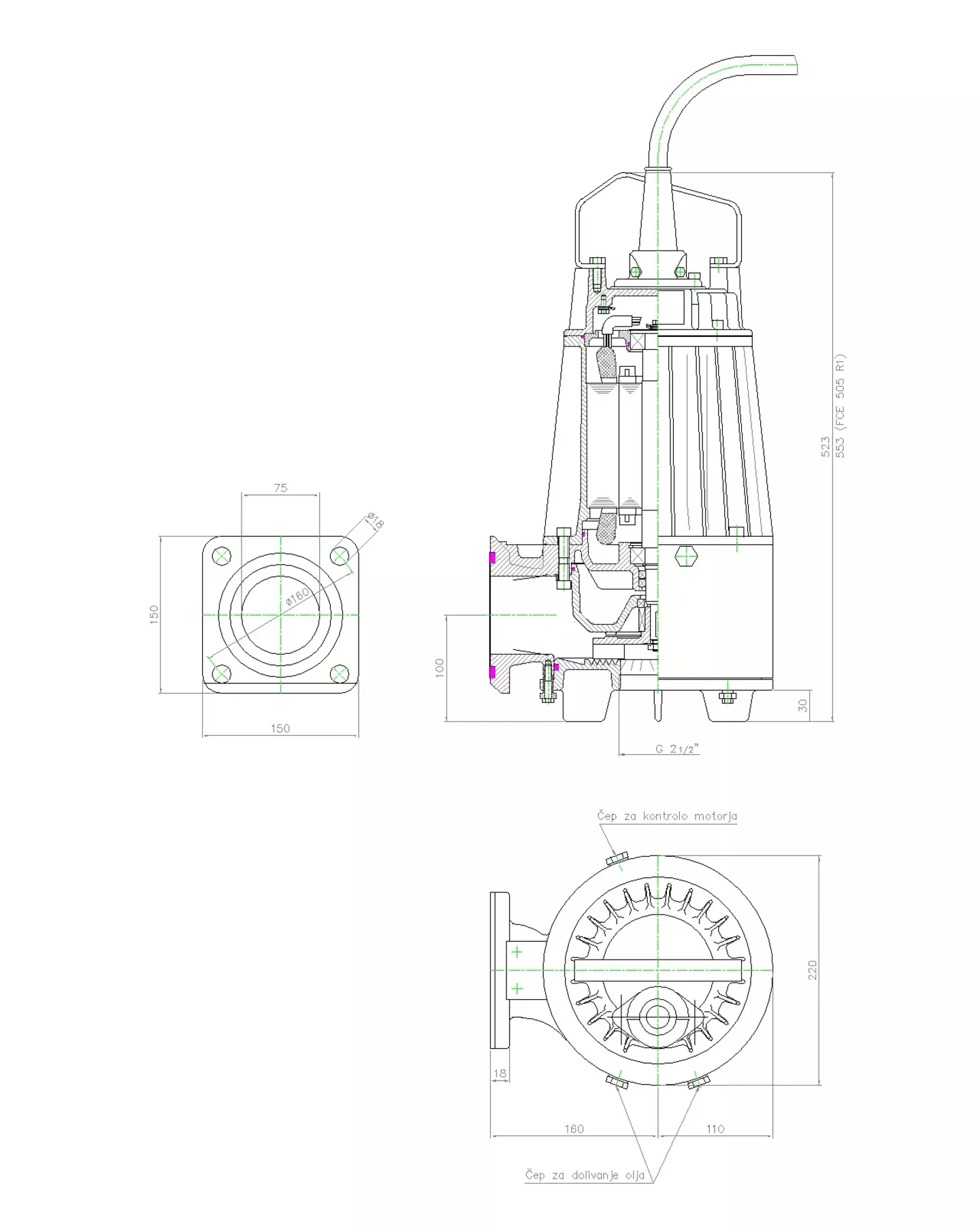

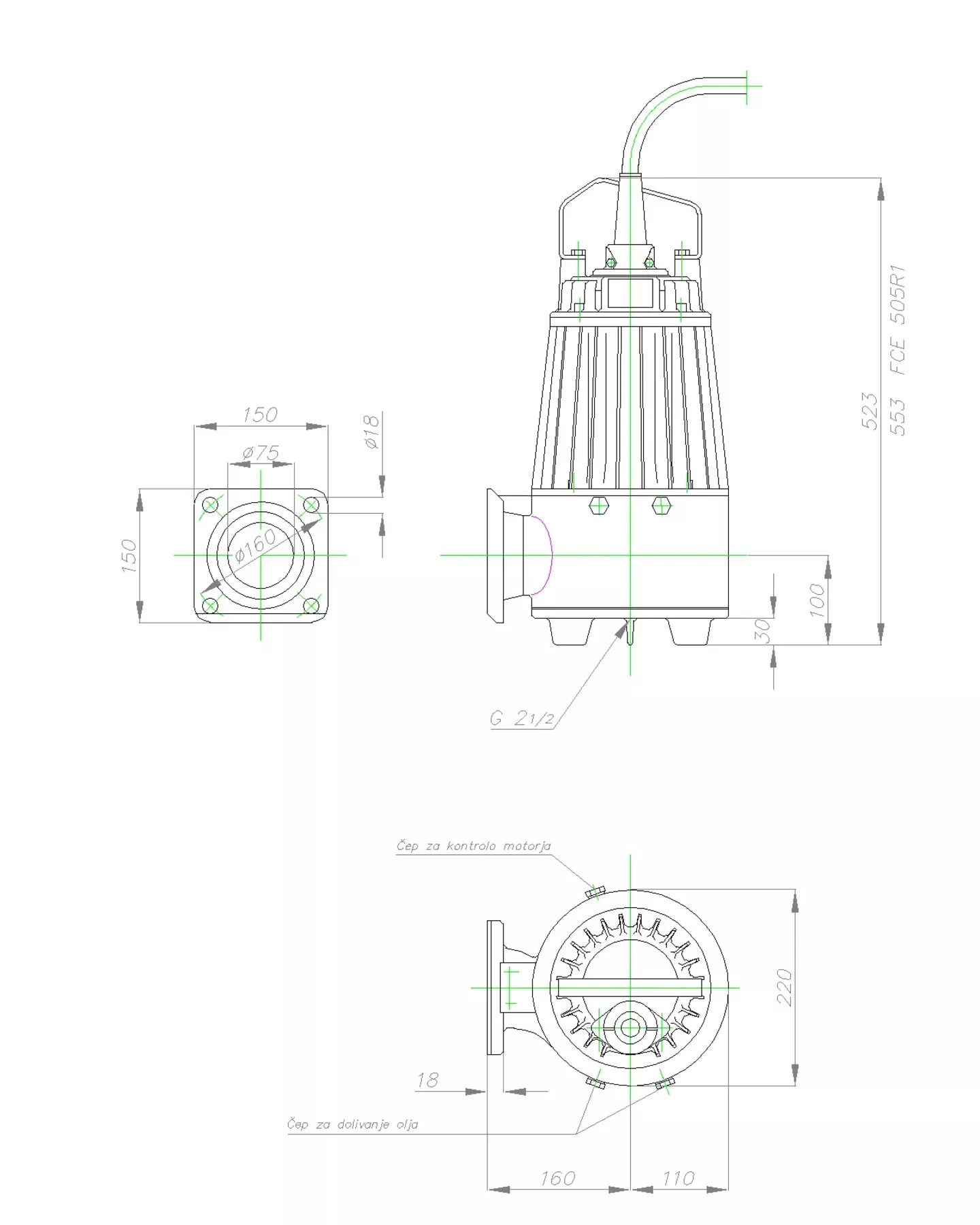

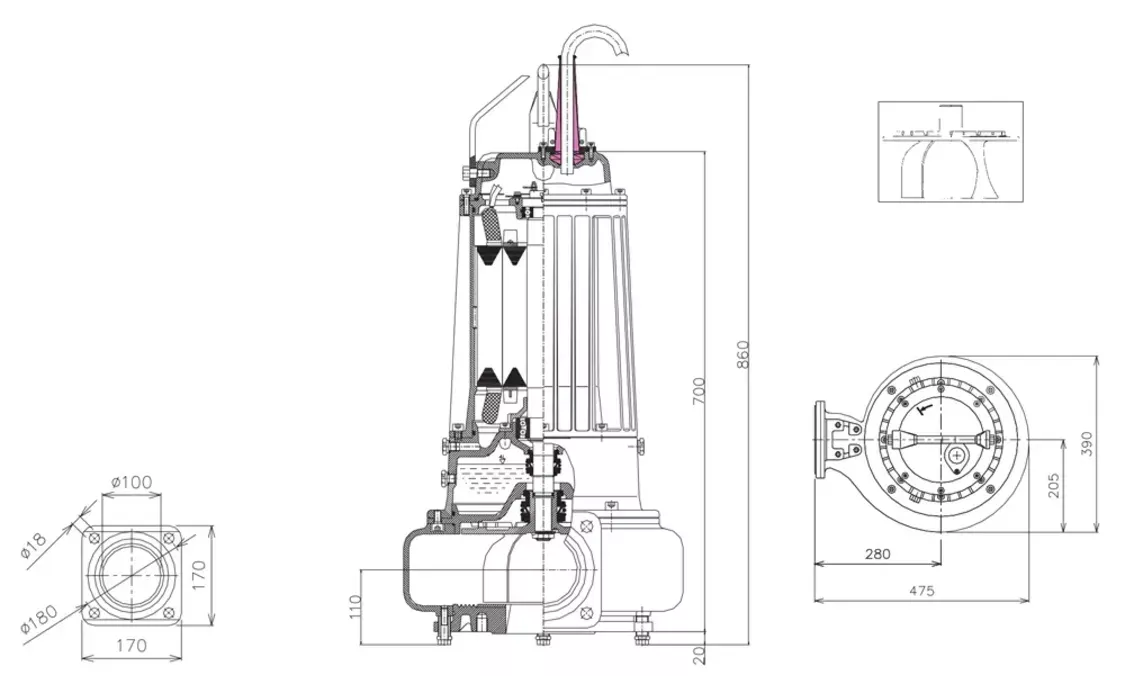

Small capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

Small capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATERS

VORTEX FC 205-207 types

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER - VORTEX. Source: ELKO ELEKTROKOVINA

SMALL CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER - VORTEX. Source: ELKO ELEKTROKOVINA

FC 205 – 207 submersible pumps are used for pumping domestic and industrial effluents and all wastewater that does not contain solid particles and sand. Only soft fibrous particles may be present in the effluent. The temperature of the liquid and the surroundings must not exceed 40°C. Manufactured with single- or three-phase underwater electric motors in dry design, the pumps are robust, made with gray cast iron components.

Pumping part: The pumps are single stage, made in a monoblock version with a joint shaft of the pump and the electric motor. The space between the pump and the electric motor is partially filled with oil which allows dry running as the oil cools and lubricates the sliding seals. The properties of the oil meet ecological requirements and do not pose a danger to the environment in the event of a spill. The open impeller version allows the passage of lumpy fibrous particles with a diameter of 10 to 100 mm. When combined with a chopping board, the impeller cuts the fibrous impurities in the pumped liquid to prevent clogging of the pipeline. A free-flow pump is also possible. The housings are made of gray cast iron, while shafts and screws are made of stainless steel and are resistant to mild acids, sludge water and silicates.

Electric motor: Underwater single-phase or three-phase asynchronous motor cooled with ambient medium temperature up to 40°C with additional power for operation in unsinkable version. The winding is of class F (155°C) with IP68 degree of protection. Single-phase motors have a permanently connected electrical cabinet (with capacitors), while three-phase motors have only a cable with the lengths of 8 and 10 m. The electric motor is dimensioned in such a way that it also allows a dry installation of the pump next to the collector.

Pump installation: Wet installation (stable or portable) is common, as the pump is immersed in the liquid it is pumping. In doing so, the liquid cools the electric motor. With a stable installation in the shaft, an accessory with a lock is used, which enables quick installation of the pump and easy lifting of the pump without entering the shaft during maintenance work. With the accessories, two 2″ pipes are installed in the shaft which guide the pump when lowered into the shaft. Portable pumps, which are moved from shaft to shaft, are equipped with accessories that contain elbows for the connection of flexible pipes. The pumps are therefore equipped with a threaded or flanged suction connection, as shown in the sketches in the catalog. The fluid level in the manifold must always be above the pump pressure connection. This will prevent the formation of an air bag in the pump. Therefore, with FC(E) pumps, the corresponding accessories can also be used for mounting, as the P-FC-Z accessories can be used to quickly lower and automatically connect the pump in the shaft, and the P-FC-P accessories can be used to equip portable pumps.

FITTINGS:

Lock fitting P-FC-Z 80 for pumps with DN 80 connection

Fitting for portable version P-FC-P 80 for pumps with DN 80 connection

Main purpose of use:

for biological wastewater or feces pumping systems

fecal water pumping

industrial purposes

for treatment plants

for pumping stations

agriculture

home use

construction

construction grounds, flooded basements, shafts

Technical characteristics:

Flow: from 48 to 54m3/h

Lifting pumping height: up to 8.2m

Engine power: 1.25 ÷ 1.8kW

Power supply: 3-phase (400V)

Medium temperature: from 0°C to + 40°C

Installation depth: up to 8m in the medium

Weight: 51 – 54kg

Small capacity submersible pumps for fecal water - vortex, Q/H diagram. Source: ELKO ELEKTROKOVINA

Small capacity submersible pumps for fecal water - vortex, Q/H diagram. Source: ELKO ELEKTROKOVINA

Small capacity submersible pumps for fecal water - vortex, drawing. Source: ELKO ELEKTROKOVINA

Small capacity submersible pumps for fecal water - vortex, drawing. Source: ELKO ELEKTROKOVINA

MEDIUM CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATERS

FC 1005-1409 types

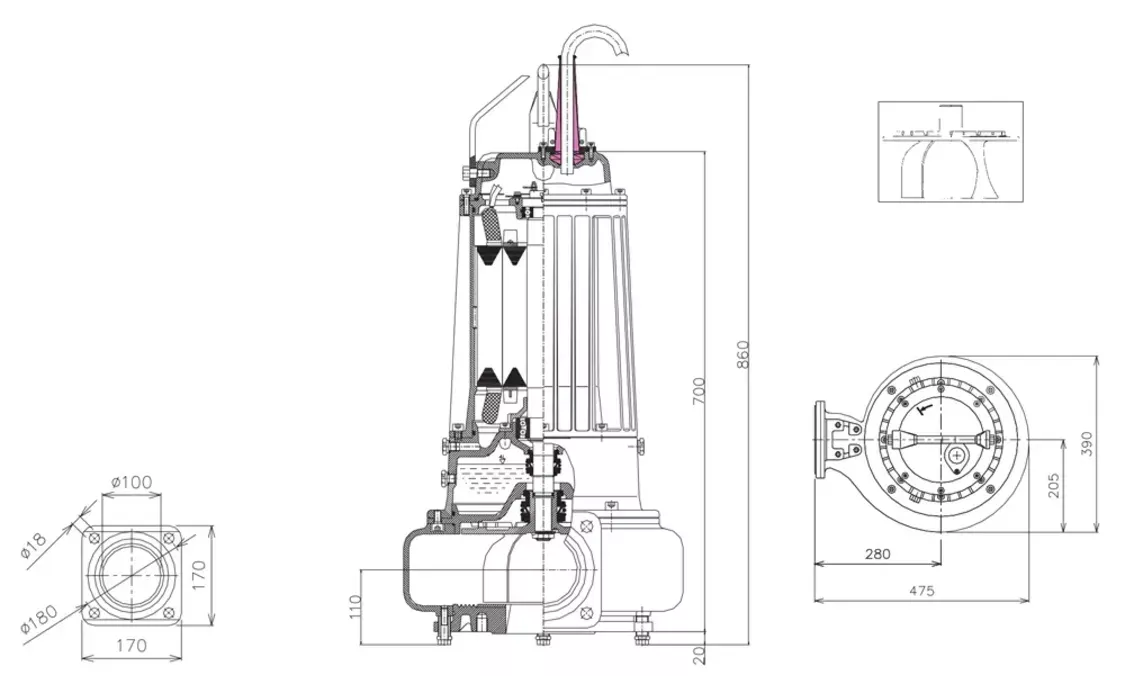

MEDIUM CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

MEDIUM CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

FC 1005 – 1409 submersible pumps are used for pumping domestic and industrial effluents and all wastewater that does not contain solid particles and sand. Only soft fibrous particles may be present in the effluent. The temperature of the liquid and the surroundings must not exceed 40°C. Manufactured with single- or three-phase underwater electric motors in dry design, the pumps are robust, made with gray cast iron components.

Pumping part: The pumps are single stage, made in a monoblock version with a joint shaft of the pump and the electric motor. The space between the pump and the electric motor is partially filled with oil which allows dry running as the oil cools and lubricates the sliding seals. The properties of the oil meet ecological requirements and do not pose a danger to the environment in the event of a spill. The open impeller version allows the passage of lumpy fibrous particles with a diameter of 10 to 100 mm. When combined with a chopping board, the impeller cuts the fibrous impurities in the pumped liquid to prevent clogging of the pipeline. A free-flow pump is also possible. The housings are made of gray cast iron, while shafts and screws are made of stainless steel and are resistant to mild acids, sludge water and silicates.

Electric motor: Underwater single-phase or three-phase asynchronous motor cooled with ambient medium temperature up to 40°C with additional power for operation in unsinkable version. The winding is of class F (155°C) with IP68 degree of protection. Single-phase motors have a permanently connected electrical cabinet (with capacitors), while three-phase motors have only a cable with the lengths of 8 and 10 m. The electric motor is dimensioned in such a way that it also allows a dry installation of the pump next to the collector.

Pump installation: Wet installation (stable or portable) is common, as the pump is immersed in the liquid it is pumping. In doing so, the liquid cools the electric motor. With a stable installation in the shaft, an accessory with a lock is used, which enables quick installation of the pump and easy lifting of the pump without entering the shaft during maintenance work. With the accessories, two 2″ pipes are installed in the shaft which guide the pump when lowered into the shaft. Portable pumps, which are moved from shaft to shaft, are equipped with accessories that contain elbows for the connection of flexible pipes. The pumps are therefore equipped with a threaded or flanged suction connection, as shown in the sketches in the catalog. The fluid level in the manifold must always be above the pump pressure connection. This will prevent the formation of an air bag in the pump. Therefore, with FC(E) pumps, the corresponding accessories can also be used for mounting, as the P-FC-Z accessories can be used to quickly lower and automatically connect the pump in the shaft, and the P-FC-P accessories can be used to equip portable pumps.

FITTINGS:

Lock fitting P-FC-Z 80 for pumps with DN 80 connection

Fitting for portable version P-FC-P 80 for pumps with DN 80 connection

Main purpose of use:

for biological wastewater or feces pumping systems

fecal water pumping

industrial purposes

for treatment plants

for pumping stations

agriculture

home use

construction

construction grounds, flooded basements, shafts

Technical characteristics:

Flow: from 108 to 162m3/h

Lifting pumping height: up to 15.5m

Engine power: 3 ÷ 5,5kW

Power supply: 3-phase (400V)

Medium temperature: from 0°C to + 40°C

Installation depth: up to 10m in the medium

Weight: 130 – 140kg

Medium capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

Medium capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

Medium capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

Medium capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

LARGE CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATERS

FC 2012-3018 types

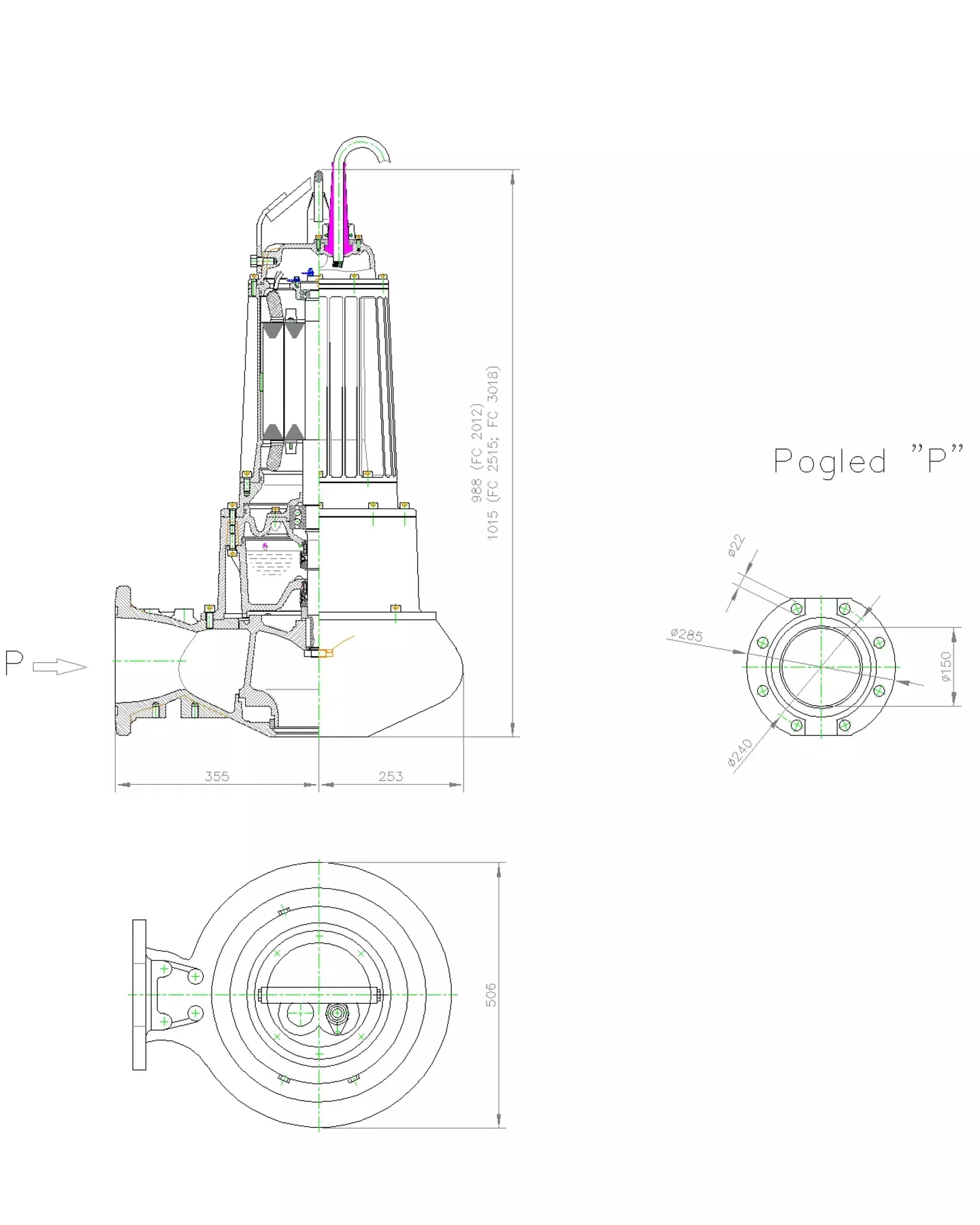

LARGE CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

LARGE CAPACITY SUBMERSIBLE PUMPS FOR FECAL WATER. Source: ELKO ELEKTROKOVINA

FC 2012 – 3018 submersible pumps are used for pumping domestic and industrial effluents and all wastewater that does not contain solid particles and sand. Only soft fibrous particles may be present in the effluent. The temperature of the liquid and the surroundings must not exceed 40°C. Manufactured with single- or three-phase underwater electric motors in dry design, the pumps are robust, made with gray cast iron components.

Pumping part: The pumps are single stage, made in a monoblock version with a joint shaft of the pump and the electric motor. The space between the pump and the electric motor is partially filled with oil which allows dry running as the oil cools and lubricates the sliding seals. The properties of the oil meet ecological requirements and do not pose a danger to the environment in the event of a spill. The open impeller version allows the passage of lumpy fibrous particles with a diameter of 10 to 100 mm. When combined with a chopping board, the impeller cuts the fibrous impurities in the pumped liquid to prevent clogging of the pipeline. A free-flow pump is also possible. The housings are made of gray cast iron, while shafts and screws are made of stainless steel and are resistant to mild acids, sludge water and silicates.

Electric motor: Underwater three-phase asynchronous motor cooled with ambient medium temperature up to 40°C with additional power for operation in unsinkable version. The winding is of class F (155°C) with IP68 degree of protection. Three-phase motors have a cable with the lengths of 8 and 10 m. For electric motors with powers above 7.5 kW, there is no possibility of dry start in the unsinkable version.

Pump installation: Wet installation (stable or portable) is common, as the pump is immersed in the liquid it is pumping. In doing so, the liquid cools the electric motor. With a stable installation in the shaft, an accessory with a lock is used, which enables quick installation of the pump and easy lifting of the pump without entering the shaft during maintenance work. With the accessories, two 2″ pipes are installed in the shaft which guide the pump when lowered into the shaft. Portable pumps, which are moved from shaft to shaft, are equipped with accessories that contain elbows for the connection of flexible pipes. The pumps are therefore equipped with a threaded or flanged suction connection, as shown in the sketches in the catalog. The fluid level in the manifold must always be above the pump pressure connection. This will prevent the formation of an air bag in the pump. Therefore, with FC(E) pumps, the corresponding accessories can also be used for mounting, as the P-FC-Z accessories can be used to quickly lower and automatically connect the pump in the shaft, and the P-FC-P accessories can be used to equip portable pumps.

FITTINGS:

Lock fitting P-FC-P 150 for pumps with DN 150 connection

Main purpose of use:for biological wastewater or feces pumping systems

fecal water pumping

industrial purposes

for treatment plants

for pumping stations

agriculturež

home use

construction

construction grounds, flooded basements, shafts

Technical characteristics:

Flow: from 240 to 290m3/h

Lifting pumping height: up to 23m

Engine power: 7,5 ÷ 15kW

Power supply: 3-phase (400V)

Medium temperature: from 0°C to + 40°C

Installation depth: up to 10m in the medium

Weight: 220 – 280kg

Large capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

Large capacity submersible pumps for fecal water, Q/H diagram. Source: ELKO ELEKTROKOVINA

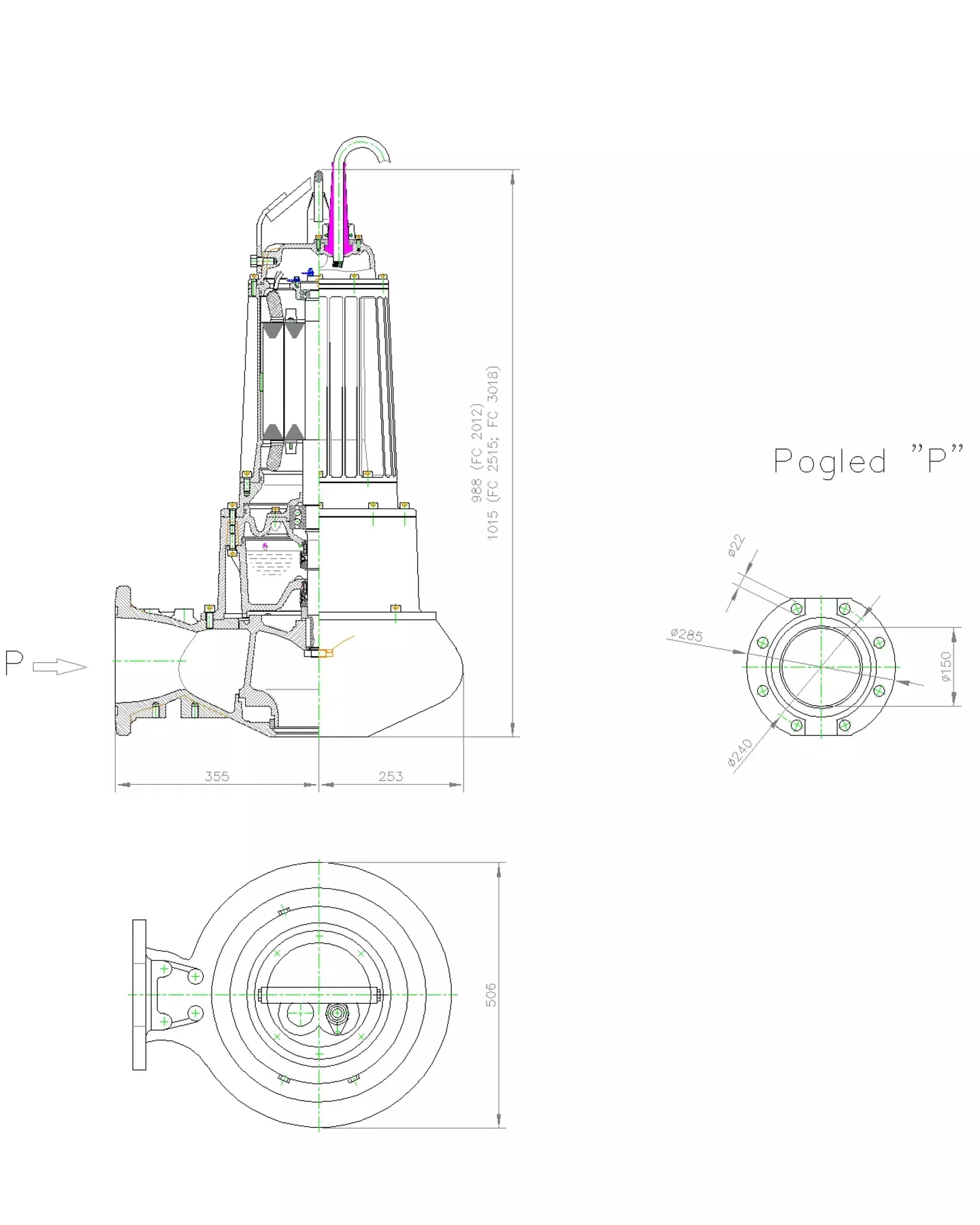

Large capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

Large capacity submersible pumps for fecal water, drawing. Source: ELKO ELEKTROKOVINA

All detailed descriptions and characteristics are available in catalogue which you can recive via E-mail. Write us on our E-mail info@s-ei.eu

Following your request via E-mail you will recive current price lists. We are available on: info@s-ei.eu

Aug 12, 2025